Rapid Prototyping

Every successful project begins with a solid prototype. At Lamothermic, we bring your concepts to life using advanced prototyping techniques that help you refine your designs before moving into full production. Whether you start with a rough sketch, a detailed 3D model, or an idea from a conversation, our prototyping process allows you to test, explore, and perfect the form, fit, and function of your parts, turning your vision into reality.

How Is a Prototype Different?

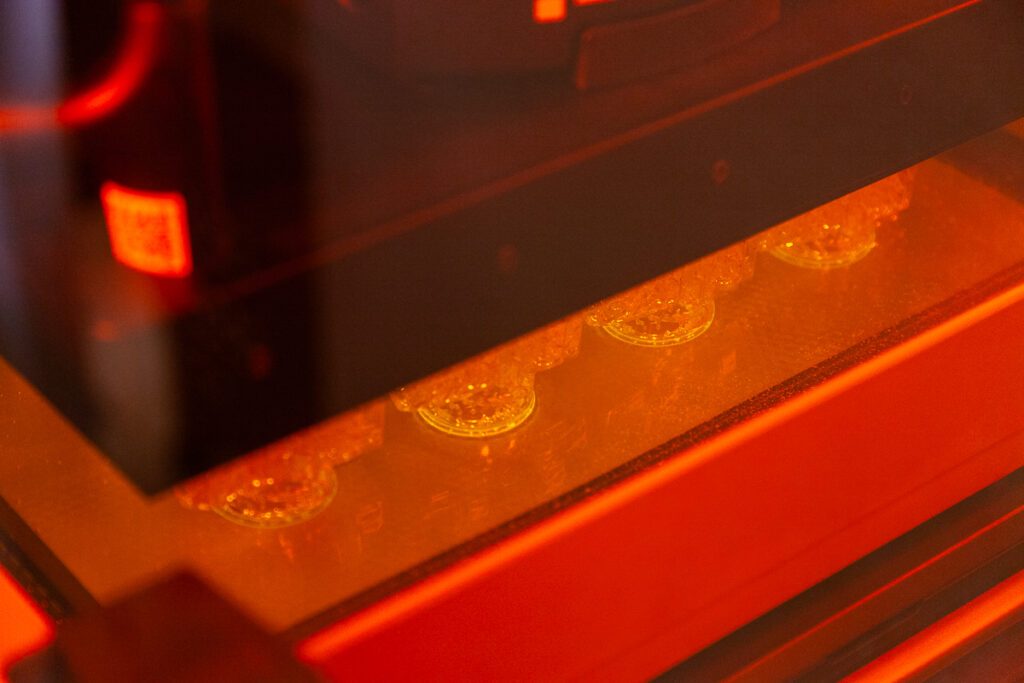

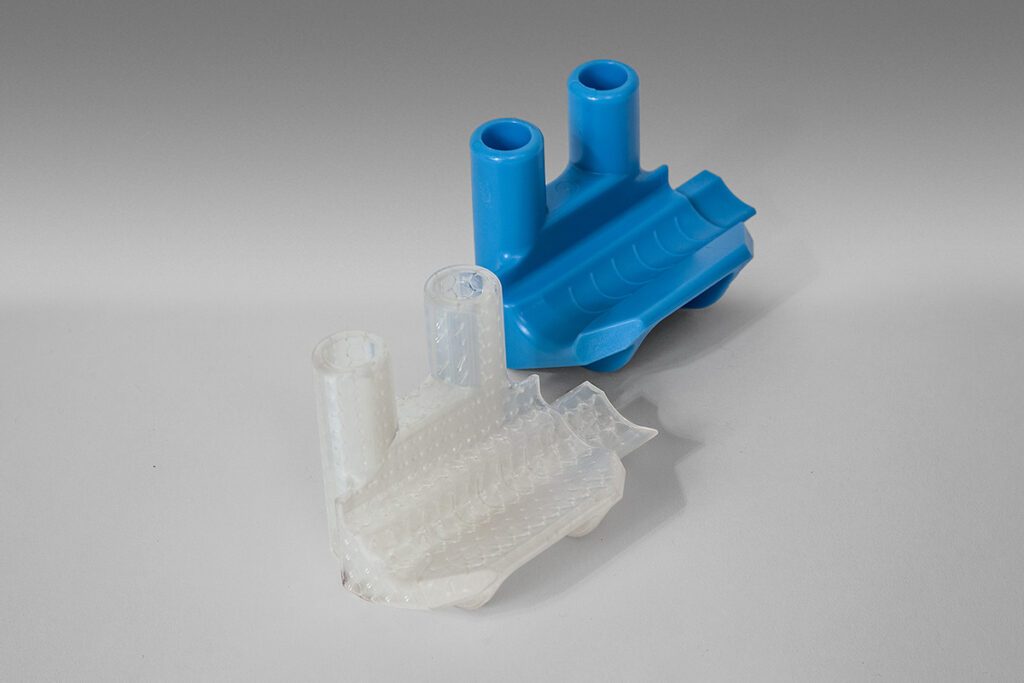

Traditionally, wax patterns are created using an aluminum mold. Which is then used to form a ceramic shell for casting. With rapid prototyping, we streamline this process by eliminating the aluminum mold and using additive manufacturing to produce patterns directly. This approach offers greater flexibility and faster turnaround times, allowing you to test designs without the need for hard tooling.

Why Rapid Prototype?

Lamothermic’s rapid prototyping capabilities offer significant advantages:

- Faster Turnaround

Printed patterns are typically ready within a week, and metal prototypes can be delivered in just 3 to 4 weeks, helping you get to market faster and stay ahead of competitors. This speed allows for quicker testing and validation of your designs.

- Cost-Effective

Skip the expense of creating hard tooling and reduce prototyping costs while maintaining high-quality results, making prototyping accessible for projects of any scale. This ensures you get the most value out of your investment.

- Efficient Iteration

Quickly refine and adjust designs before committing to final tooling, ensuring your part meets all specifications with minimal delay and greater design flexibility. Each iteration allows you to improve functionality and address issues before full production.

- Shortened Lead Times

Cut production timelines by 6 to 8 weeks compared to traditional tooling methods, keeping your project ahead of schedule and your operations running smoothly. This advantage enhances your ability to meet tight deadlines.

- Reliable Performance

Prototype castings made from 3D-printed patterns perform identically to those made from wax patterns, offering dependable quality for testing and evaluation without process constraints. This reliability ensures confidence in moving to full-scale production.

New Large-Format 3D Printing Capabilities

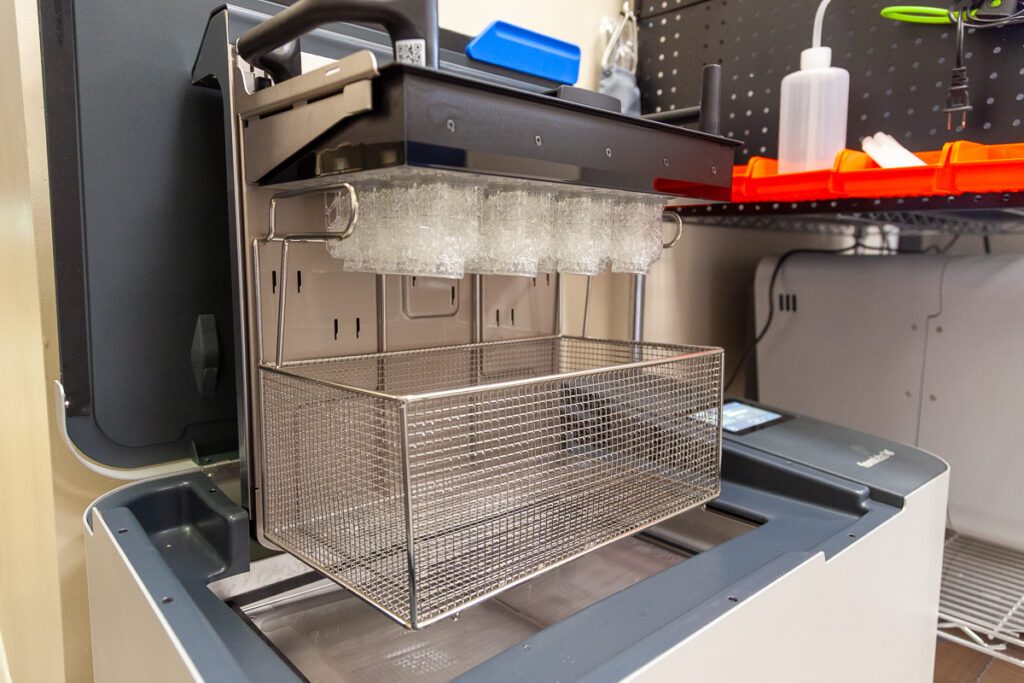

To further enhance our rapid prototyping capabilities, we recently added a Formlabs Form 4L 3D printer to our in-house equipment lineup. This addition allows us to better serve our customers with faster turnaround, larger print volumes, and exceptional accuracy — all while maintaining cost efficiency.

Large Format, High-Resolution Prototyping

- Build volume of 353 x 196 x 350mm (13.9 x 7.7 x 13.8 inches)

- Ideal for printing large individual parts or multiple components at once

- Enables full-size prototypes in a single print run

Fast Turnaround Times

- Rapid production of prototypes with shorter lead times

- Efficient in-house operation reduces wait time and shipping costs

- Keeps your projects on schedule and moving forward

Exceptional Detail and Surface Quality

- High dimensional accuracy for test-fitting and validation

- Fine surface finishes for highly realistic prototypes

- Suitable for visual models, functional testing, and casting patterns

Advanced 3D Scanning & Measurement

To complement our large-format printing, we utilize the Keyence VL-800 3D Scanner. This high-precision system enhances both prototyping and quality control by providing:

- Micron-level resolution for accurate dimensional verification of complex geometries

- Automated scanning and data processing that reduce inspection time compared to traditional CMMs

- Seamless export of measurement data into CAD and quality systems, supporting PPAP, FAIR, and continuous improvement

- Statistically consistent results, enabling reliable capability studies

- Reverse engineering capabilities to create 3D models for root-cause analysis and design refinement

- Reduced scrap, rework, and inspection bottlenecks through faster, more accurate feedback

Ready to Discuss Your Next Project?

Partner with Lamothermic to design, engineer, and prototype the parts you need for a successful production run. Our team is ready to help you bring your ideas to life, faster. Contact us today to get started!